In evaluating CCU (Carbon Capture and Utilization) processes, accurate performance assessment of the CO₂ capture process is essential. We support process performance evaluation based on material and energy balances using aspenONE process modeling tools.

In particular, we provide consulting services for modeling and evaluating gas absorption processes using Aspen Plus®, based on proprietary expertise accumulated through past projects.

In the analysis of CO₂ absorption processes with chemical or physical absorbents, Aspen Plus®, the de facto standard tool in the industry, enables high-accuracy modeling of state-of-the-art chemical absorption processes.

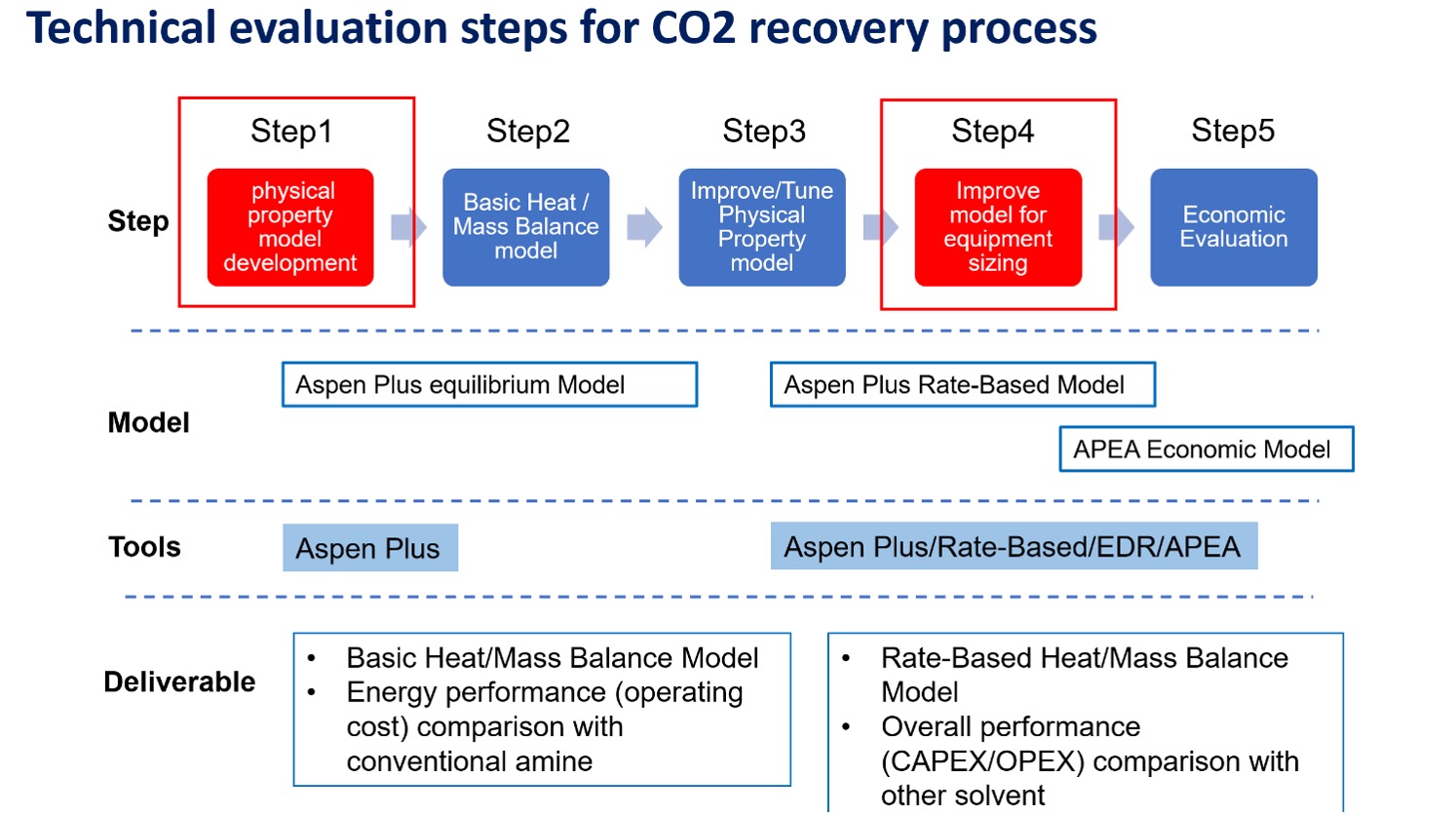

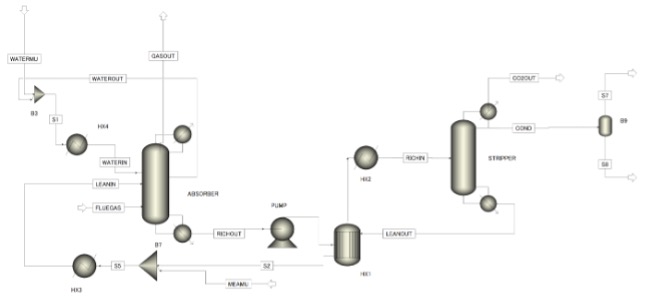

At our company, we use Aspen Plus® to build thermodynamic property models and develop flowsheet models for CO₂ capture processes, including the absorber, stripper, and associated auxiliary equipment. We construct simulation models that reflect expected process operating data, such as pilot or commercial plant data, and perform parameter tuning as needed. In addition to developing material and energy balance–based models for the CO₂ capture process, we also support energy optimization through the evaluation of heat recovery systems using pinch technology.

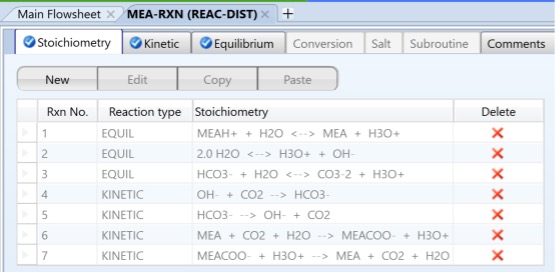

In cases where liquid-phase ionic reactions—such as those in amine-based processes or with ionic liquids—play a key role, we utilize the reaction modeling capabilities of Aspen Plus®, which support both equilibrium and kinetic reaction models.

We assist in building more practical and applicable models by performing reaction parameter fitting based on experimental data or literature values, leveraging our proprietary expertise.

We are fully equipped to respond flexibly to needs such as “We want simulations that match experimental results” or “We need a model that reproduces the conditions reported in the literature.”

Furthermore, if you are evaluating a newly developed absorbent, we provide support for fitting physical property parameters and estimating properties, enabling predictive modeling of the behavior of new solvent systems within Aspen Plus®.

We also support a wide range of case studies.

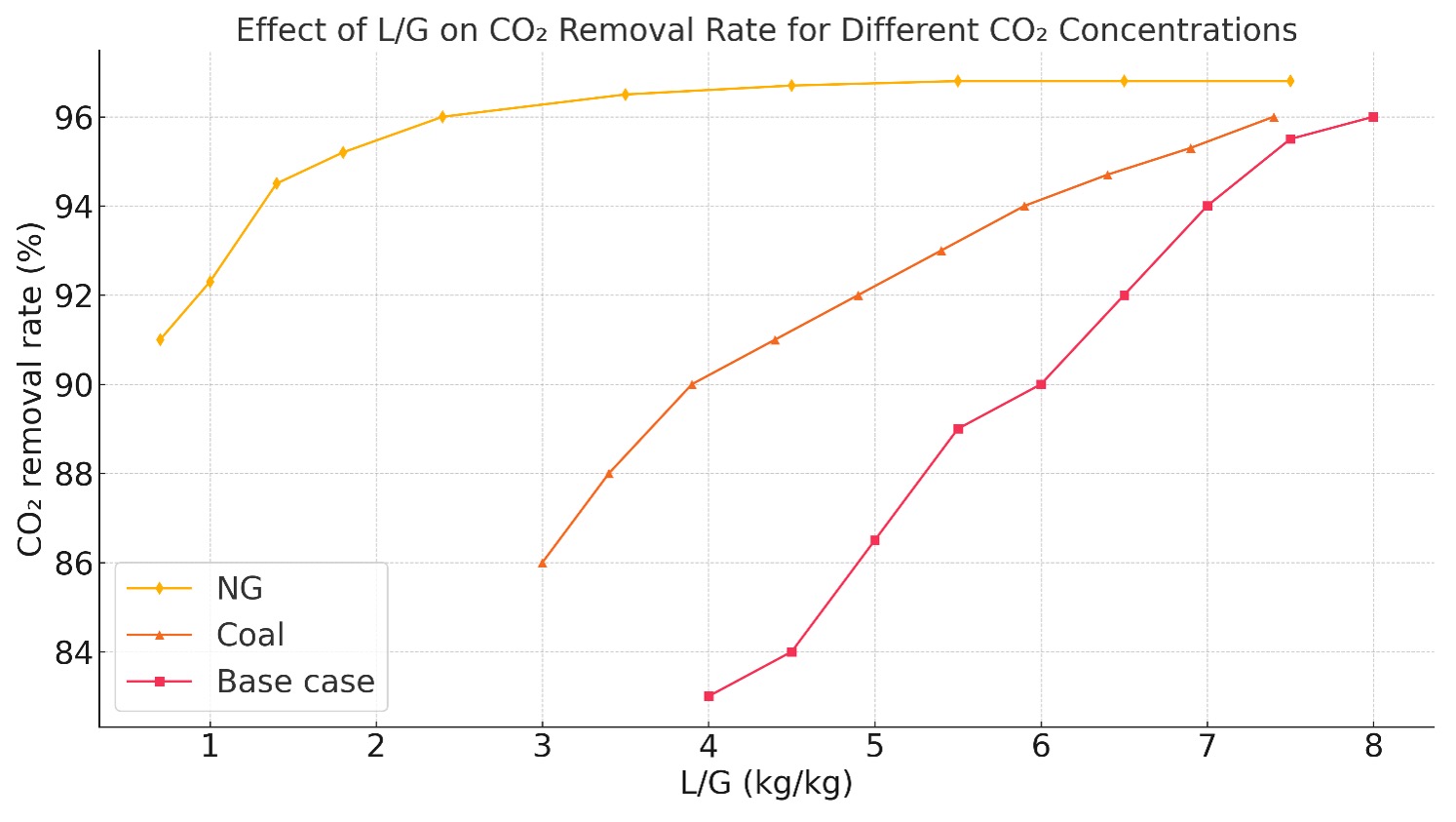

For example, in CO₂ capture processes using amine absorbents, it is essential to examine various operating parameters such as operating pressure, lean/rich solvent loading, and liquid-to-gas ratio (L/G).

We assist with simulation studies tailored to your specific objectives, including evaluations of column internals and behavior prediction during scale-up.

If you are considering the design or optimization of a CO₂ capture process, please feel free to contact us.

Our experienced engineers will propose the most suitable solution tailored to your specific challenges.